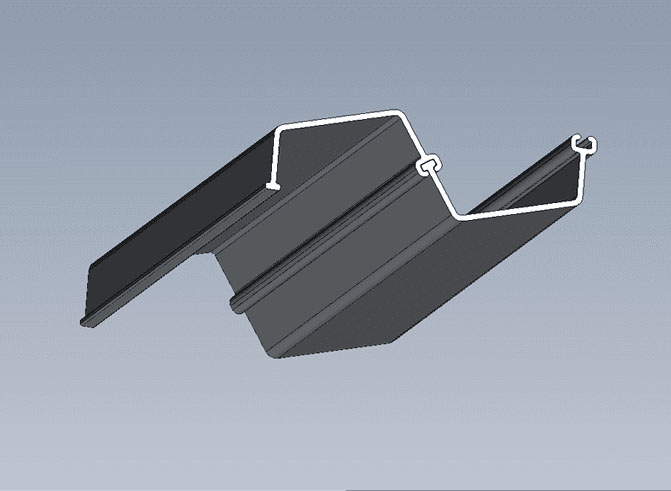

PVC Sheet Piling

PVC sheet piling is the pile with connecting locks for the building up of a solid protective wall. It is an analogue of Larssen steel sheet pile, but made of heavy-duty PVC (polyvinyl chloride) and is widely used in hydrotechnical and engineering construction. Possessing high mechanical resistance, it is stable to rotting, corrosion and rust, and the PVC characteristics allow to use it in aggressive environmental conditions.

About the manufacturer STIMEX

In 2016 STIMEX company started the production of new product - the PVC sheet piling This material is actively used for bank protection of water basin, creation of canals, for protection from groundwater and hazardous substance leakage, reinforcing of road slope and bridge footing. The high quality of our products are achieved by using of European quality raw materials, advanced technology and modern equipment (extruders of well- known German company WEBER).

Application of

PVC sheet piling

The improvement and active use coastlines of different water basins are becoming very important today. So, the main point is the coast protection: to protect banks and builds against the effects of water environment

The Advantages

Low cost effective of vinyl sheet pile

The less weight reduce the transportation costs

Easy to install. No heavy equipment

Resistance to seasonal temperature drop

Lack of deformation and dimensional changes

UV-Resistant

Durability

50+ years

The Hydrotechnical Construction

-

01 The construction of dams and dikes

-

02 The creation of water areas and beaches

-

03 The construction of piers and berth

-

04 Drainage chanels

-

05 Reclamation canals for agricultural land

-

06 Adjusting the direction and current speed of water

-

07 Protection from undermining and flood

The Engeneering Construction

-

01 The construction and land reclamation of refuse dump

-

02 The technical tanks

-

03 The construction of slime storage

-

04 The guarding of chemically active storage and dirty areas

Technical

Specifications

The most up-to-date technological advances in the extrusion and application of modern chemical additives allow to create a product with high running ability – sheet piling made of PVC (polyvinyl chloride)

PVC sheet pile LZ-260/6

| Section width | mm | 260 |

| Section depth | mm | 66 |

| Thickness | mm | 5.0 |

| Weight per m2 | kg | |

| Section Moment (Z) | cm3/m | 86.2 |

| Moment of inertia | cm4/m | 382.30 |

| Charpy impact strength | kJ/m2 | ≥ 40 |

| Strength level | kN-m/m | 1.6 |

PVC sheet pile LD-200/6

| Section width | mm | 200 |

| Section depth | mm | 60 |

| Thickness | mm | 6 |

| Weight per m2 | kg | 14.00 |

| Section Moment (Z) | cm3/m | 376.6 |

| Moment of inertia | cm4/m | 2658.6 |

| Charpy impact strength | kJ/m2 | >40 |

| Strength level | kN-m/m | 9.4 |

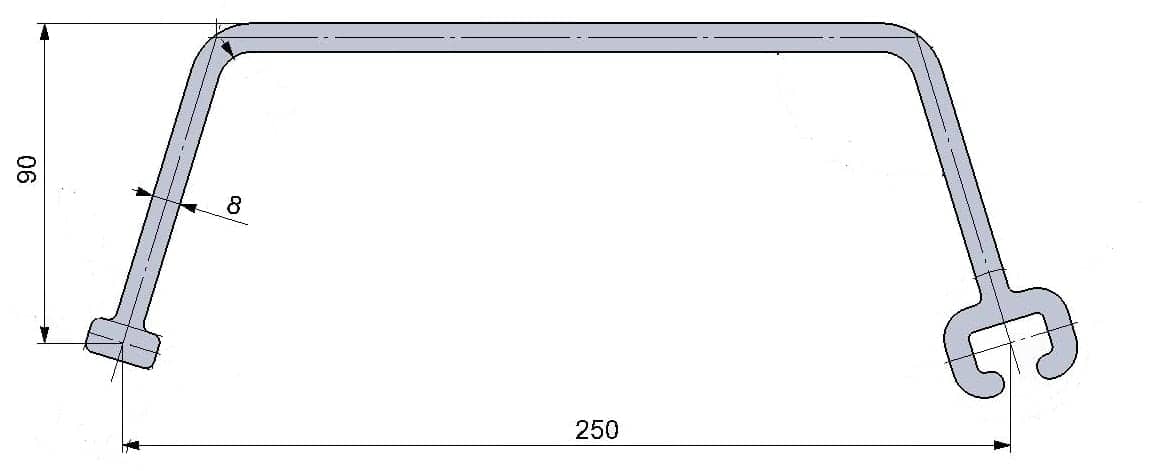

PVC sheet pile LD-250/8

| Section width | mm | 250 |

| Section depth | mm | 90 |

| Thickness | mm | 8 |

| Weight per m2 | kg | 21.32 |

| Section Moment (Z) | cm3/m | 795.70 |

| Moment of inertia | cm4/m | 8672.70 |

| Charpy impact strength | kJ/m2 | >40 |

| Strength level | kN-m/m | 18.0 |

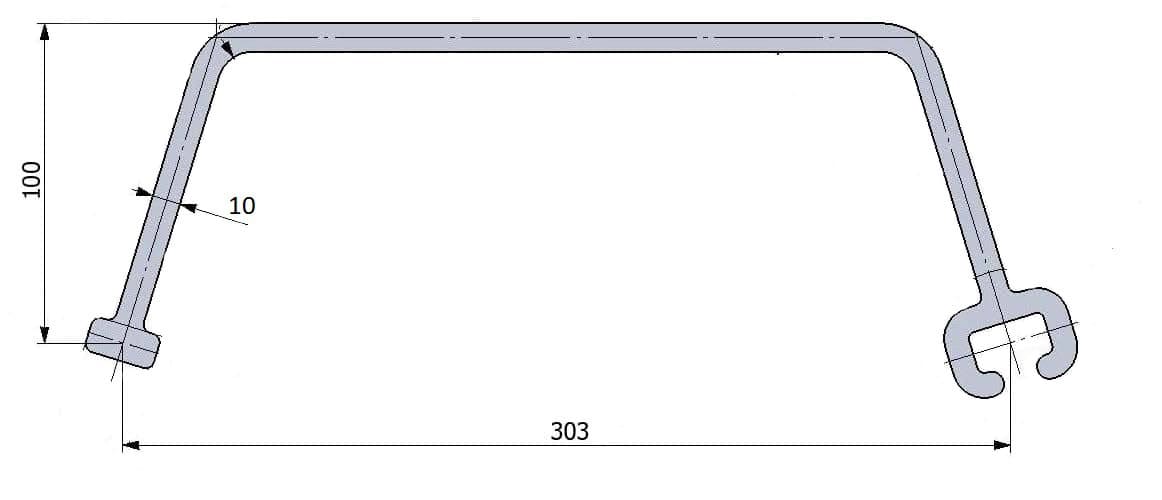

PVC sheet pile LD-303/10

| Section width | mm | 303 |

| Section depth | mm | 100 |

| Thickness | mm | 10 |

| Weight per m2 | kg | |

| Section Moment (Z) | cm3/m | 1484.50 |

| Moment of inertia | cm4/m | 17818.0 |

| Charpy impact strength | kJ/m2 | ≥ 40 |

| Strength level | kN-m/m | 31.5 |

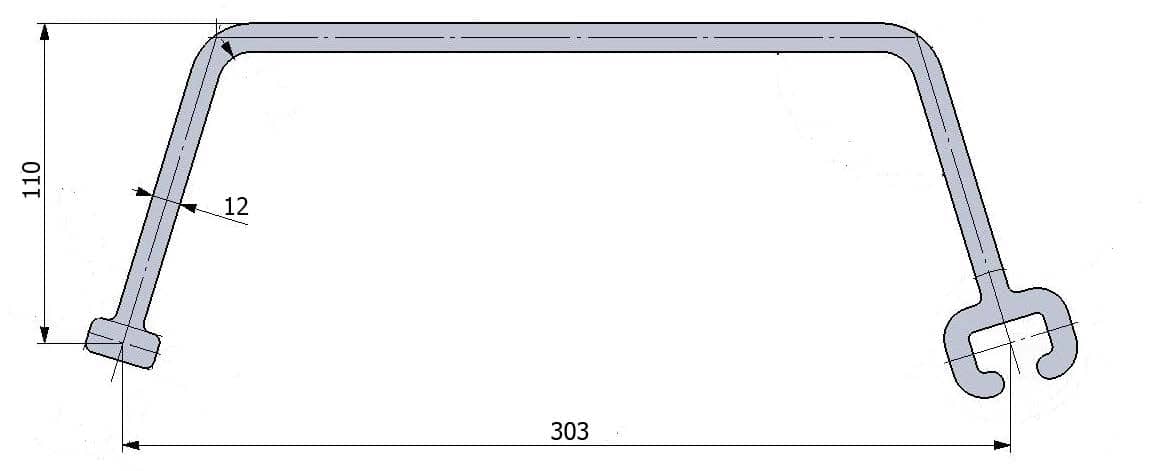

PVC sheet pile LD-303/12

| Section width | mm | 303 |

| Section depth | mm | 110 |

| Thickness | mm | 12 |

| Weight per m2 | kg | 30.99 |

| Section Moment (Z) | cm3/m | 1661.30 |

| Moment of inertia | cm4/m | 21084.40 |

| Charpy impact strength | kJ/m2 | >40 |

| Strength level | kN-m/m | 37.2 |

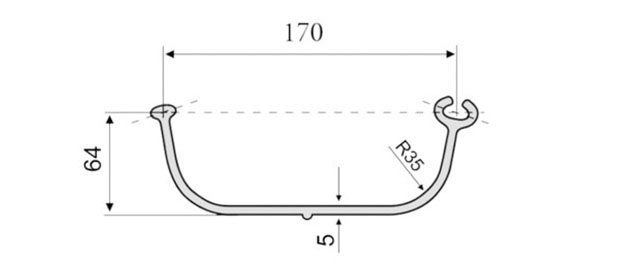

PVC sheet pile EPT-19

| Cross section width of sheet piles | mm | 170 |

| Cross section height of sheet piles | mm | 64 |

| Sheet pile wall thickness | mm | 5 |

| Cross section area | mm | 1498 |

| Mass of the sheet pile per 1 linear meter | kg | 2.3 |

| Length from 1 to 12 meter |

PVC sheet pile EPT-29

| Cross section width of sheet piles | mm | 290 |

| Cross section height of sheet piles | mm | 119 |

| Sheet pile wall thickness | mm | 9 |

| Cross section area | mm | 4826 |

| Mass of the sheet pile per 1 linear meter | kg | 7.3 |

| Mass 1 square meter of the wall | kg | 29.2 |

| Length from 1 to 12 meters |

CERTIFICATES

Call now

or write

a message

Phone

Visit

124 City Road, London